Do you want to pack your goods more sustainably? Did you know that the right choice of packing tape can help you do so? Depending on their composition, different tapes don’t only suit diverse applications best, but they also have different carbon footprints.

Various methods for calculating a product's carbon footprint have been developed, which you can learn more about here. The calculation, for instance, accounts for the emissions caused by the production process and the raw materials used. The CO2 emissions calculated for adhesive tapes is given in kg per 1,000 square metres. However, the CO2 balance is also influenced by how well an adhesive tape works for the particular application. For instance, the associated CO2 value is lower when less material is required to create a reliable carton seal. Naturally.

The CO2 emissions of our monta Greenline range are calculated based on the “Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard“ (GHG Protocol). According to the „Cradle-to-Customer plus Waste” approach, all stages of the product life cycle were taken into account – including the extraction of raw materials, incoming logistics, production, delivery of the goods to the customer’s gate as well as the disposal of the adhesive tape and its packaging.

We reduce our carbon emissions as far as possible, as stipulated by our ISO 50001 energy certification. For all unavoidable carbon emissions caused by the monta Greenline range, we financially support certified climate projects.

Comparison of PLA, paper and reprocessed BOPP

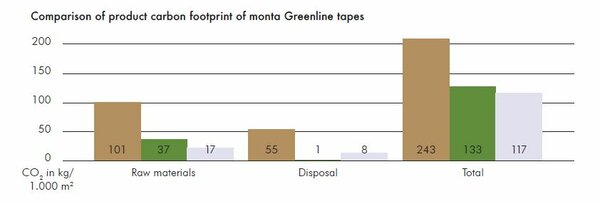

Individual products in the Greenline line show different carbon footprints, depending on the backing material used. Paper, PLA, and reprocessed BOPP tapes are among the options.

Our Greenline paper tapes are 65% bio-based and ideal for natural-looking packaging. To obtain sufficient strength, however, a relatively high material input is required. Monta biopack® (with PLA carrier) and monta reTec (based on reprocessed BOPP) are both excellent filmic alternatives. Both tapes offer sustainable aspects as well as high tear and adhesive strength. Their technical properties are similar if not identical to standard BOPP tapes.

monta biopack® is made up of around 90% bio-based materials (based on dry weight) and has been proven to be industrially compostable with a closed CO2 cycle. Because the use of virgin material can be reduced by 99%, this innovative adhesive tape has a particularly low CO2 balance overall.

Get more detailed information about the different products of our Greenline range in our product finder.