When did you last use a self-adhesive tape? Certainly it wasn’t long ago, did you ever think of all the layers it includes? We are happy to provide an insight of the technology hidden in such an everyday item, of its structure and the numerous possible modifications regarding its composition. There is a huge variety of adhesive tapes, and depending on your specific application, to achieve a perfect outcome, the right choice of tape is crucial.

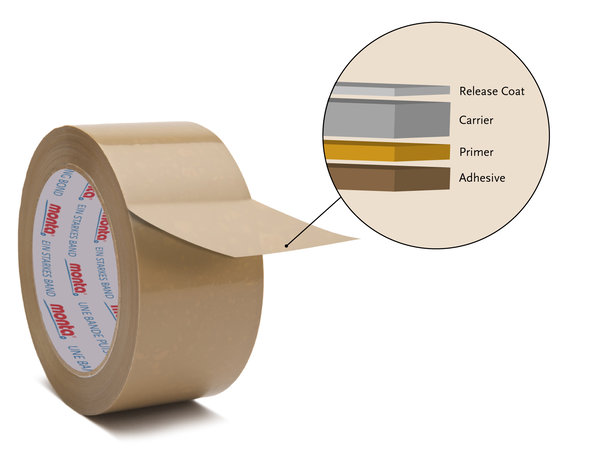

With a thickness ranging between only 0,040 and 0,080mm, most packaging tapes comprise three or four layers. The base is called backing material or carrier and in most cases is a film made of PVC, BOPP, MOPP, PET or PLA. An alternative backing material is paper with a special surface treatment which makes the tape resistant to moisture.

The back of this layer is covered with a release coat to later ensure an easy unwinding of the finished tape. Tapes which are manufactured with PVC film or which later will be coated with acrylic adhesive unroll smoothly even without release coat.

The front of the backing material gets primed with a thin and even coat of a liquid bonding agent which will later ensure a strong connection between the backing material and the adhesive. Once the primer has dried, the adhesive is added as the last layer. There are three pressure sensitive adhesive technologies to choose from: hotmelt, acrylic and natural rubber. monta only processes natural rubber adhesives which we develop and manufacture ourselves. Depending on the type of tape they are used in different formulations and coating thicknesses. They can be applied to almost any backing material.

Have a look at our product finder to discover which combination is best for your needs.